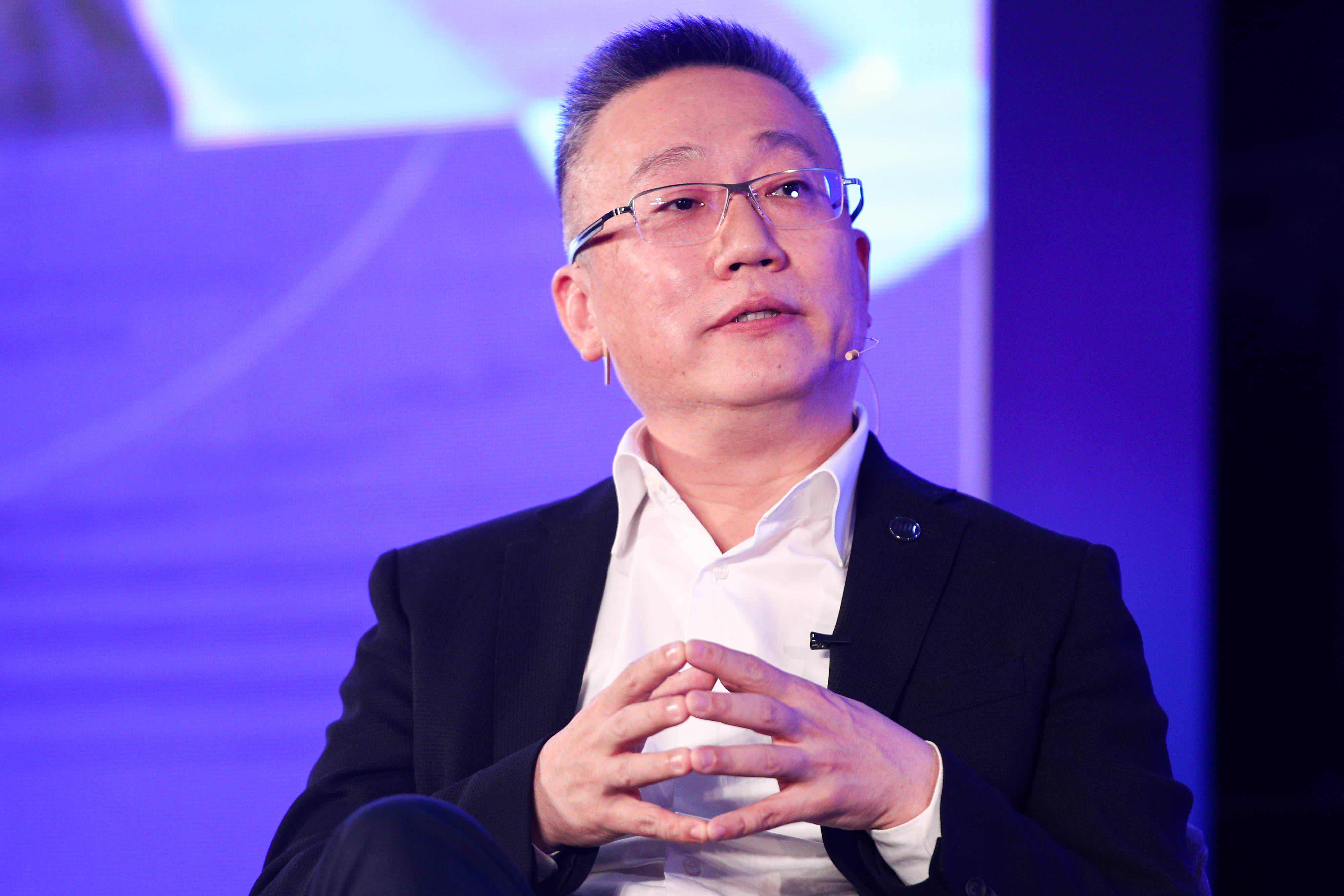

BEIJING — Covid-related restrictions have elevated manufacturing prices for Chinese language electrical automotive start-up WM Motor, at the same time as current chip and battery shortages are driving up prices, CEO Freeman Shen informed CNBC.

“Including all these items collectively, this business is a fast-growing business, however the fee a part of the equation can be going to be a problem,” Shen, additionally founder and chairman of WM Motor, stated Wednesday.

Gross sales of recent power autos — which embody battery-only and hybrid-powered automobiles — greater than doubled final 12 months in China, the world’s largest car market. The nation has develop into a hotbed for electrical automotive start-ups and a launch pad for a lot of conventional auto giants making the shift to electrical.

China rapidly managed the native unfold of the coronavirus in 2020 by imposing swift lockdowns on cities and neighborhoods. However after the emergence of the extremely transmissible omicron variant, some analysts began to query whether or not the prices of the zero-Covid coverage now outweigh the advantages.

The affect is already being felt by factories. A Chinese language ministry overseeing manufacturing stated this month the lockdowns could be a drag on industrial manufacturing within the first quarter.

Shen laid out the affect of Covid-related restrictions on his start-up:

- A chip producer in Malaysia had manufacturing issues and stopped delivering to Bosch China, which then stopped delivering to WM Motor.

- Inside China, after Covid instances emerged in Nanjing, certainly one of WM Motor’s battery cell suppliers stopped deliveries.

- In the previous few months, comparable disruptions affected two of the corporate’s suppliers within the Shangyu district of Shaoxing metropolis, close to Hangzhou.

- Covid-related restrictions on the Ningbo port space additionally stopped supply from three suppliers there.

“So, all these items have been killing us,” Shen informed CNBC.

Automakers all over the world have lower manufacturing attributable to a scarcity of semiconductors. Geopolitical tensions and overwhelming demand for chips within the wake of the pandemic contributed to a shortfall in provide that has lasted for greater than a 12 months.

Shen stated he expects the chip scarcity to enhance within the second half of this 12 months, primarily based on conversations together with his start-up’s 11 chip suppliers.

Electrical automotive battery scarcity

Nevertheless, he pointed to a different looming downside that might worsen: Rising uncooked supplies prices for batteries.

Battery-grade lithium carbonate costs have been up greater than 500% year-on-year as of earlier this month, based on S&P International Platts. The agency’s survey of business insiders launched this week discovered that 80% of respondents count on these lithium costs to stay excessive this 12 months — about 4 occasions increased than the beginning of 2021.

The battery scarcity will probably worsen as demand for electrical automobiles in China picks up within the second quarter, Shen stated. For 2022, he expects electrical automotive gross sales within the nation to just about double from final 12 months to about 5 million autos.

The surge in electrical automotive gross sales comes regardless of an general decline in passenger automotive gross sales within the final a number of months as China’s client spending slumped.

WM Motor stated it delivered a quarterly file of 15,114 autos within the final three months of 2021, bringing cumulative deliveries to 88,686 because the start-up handed over its first automotive to a buyer in 2018.

By way of deliveries, different Chinese language electrical automotive start-ups are forward of WM Motor.

Nio, Xpeng and Li Auto all asserting their 100,000th supply final 12 months.

The businesses are nonetheless far smaller than Tesla, which in China sells two of the market’s 5 best-selling electrical automobiles. Elon Musk stated in a tweet the automaker reached the far increased milestone of manufacturing 1 million automobiles in March 2020.

Shen stated provide chain challenges affected the corporate’s supply volumes final 12 months greater than client curiosity. Tesla additionally blamed provide chain points for its 2021 efficiency in its earnings launch this week.

Reassessing a Japanese manufacturing mannequin

One of many causes the pandemic disrupted the availability chain is that factories have traditionally used a longstanding Japanese mannequin of “just-in-time” or lean manufacturing, through which factories solely buy elements as wanted to scale back prices and enhance effectivity, Shen identified.

However now, the technique is altering.

“To be able to be sure to can ship your automotive, you most likely will begin considering: Now we have to waste a few of our cash to maintain some inventory,” he stated. “For a automotive firm, the most important loss could be shedding the gross sales to your buyer.”

A part of WM Motor’s gross sales technique is to work with property builders to open check drive websites in additional residential neighborhoods, whereas increase the automobiles’ autonomous driving capabilities corresponding to in parking, Shen stated.

He stated the corporate might want to elevate costs to deal with rising prices, as others within the business have already got.

For one, Tesla raised the worth for its Mannequin Y in China by 21,088 yuan ($3,300) in December to 301,840 yuan ($47,450), after subsidies. WM Motor’s automobiles are about half that value.

Journey restrictions have an effect on enterprise

Economists say China’s Covid-related journey restrictions have an effect on client spending greater than factories.

Cities incessantly change Covid testing necessities for journey, whereas flights and practice tickets can get cancelled primarily based on newly reported Covid instances.

These restrictions have additionally affected WM Motor, Shen stated. The corporate has analysis and improvement, manufacturing facility and different business-side operations in Shanghai, Chengdu, Zhejiang province and Hubei province, along with about 500 brick-and-mortar shops throughout the nation.

He stated the corporate has had to make use of extra applied sciences like digital actuality and augmented actuality to assist staff and clients talk regardless of journey restrictions.

“Now we have to make use of this type of expertise, as a result of if not, the person expertise goes to be horrible, and the effectivity goes to be very unhealthy. And we typically can’t even get issues accomplished,” Shen stated.

Requested if he had any IPO plans, Shen stated there was no information to announce on the itemizing entrance, and cited the urgent supply points.

“Clearly folks had plenty of expectation, our investor had plenty of expectation, however we’re very busy nowadays to ship our product,” he stated. “Hopefully we will get one thing to announce within the close to future.”