Synthetic intelligence is making a giant impact on the auto {industry}.

Income from gross sales of autonomous autos is anticipated to high $70 billion by 2033, in keeping with Future Market Insights. However self-driving vehicles powered by AI should not the one change — AI know-how is already being infused into car manufacturing.

associated investing information

As a part of that industry-wide pattern, the BMW Group is now shifting gears to rely extra closely on AI to create a leaner and extra environment friendly manufacturing course of.

Over the previous few years, BMW has upgraded its Spartanburg, South Carolina, plant to incorporate new AI capabilities. The manufacturing facility spans greater than 8 million sq. ft and produces about 60% of all BMWs offered within the U.S. That works out to greater than 1,500 autos produced every day.

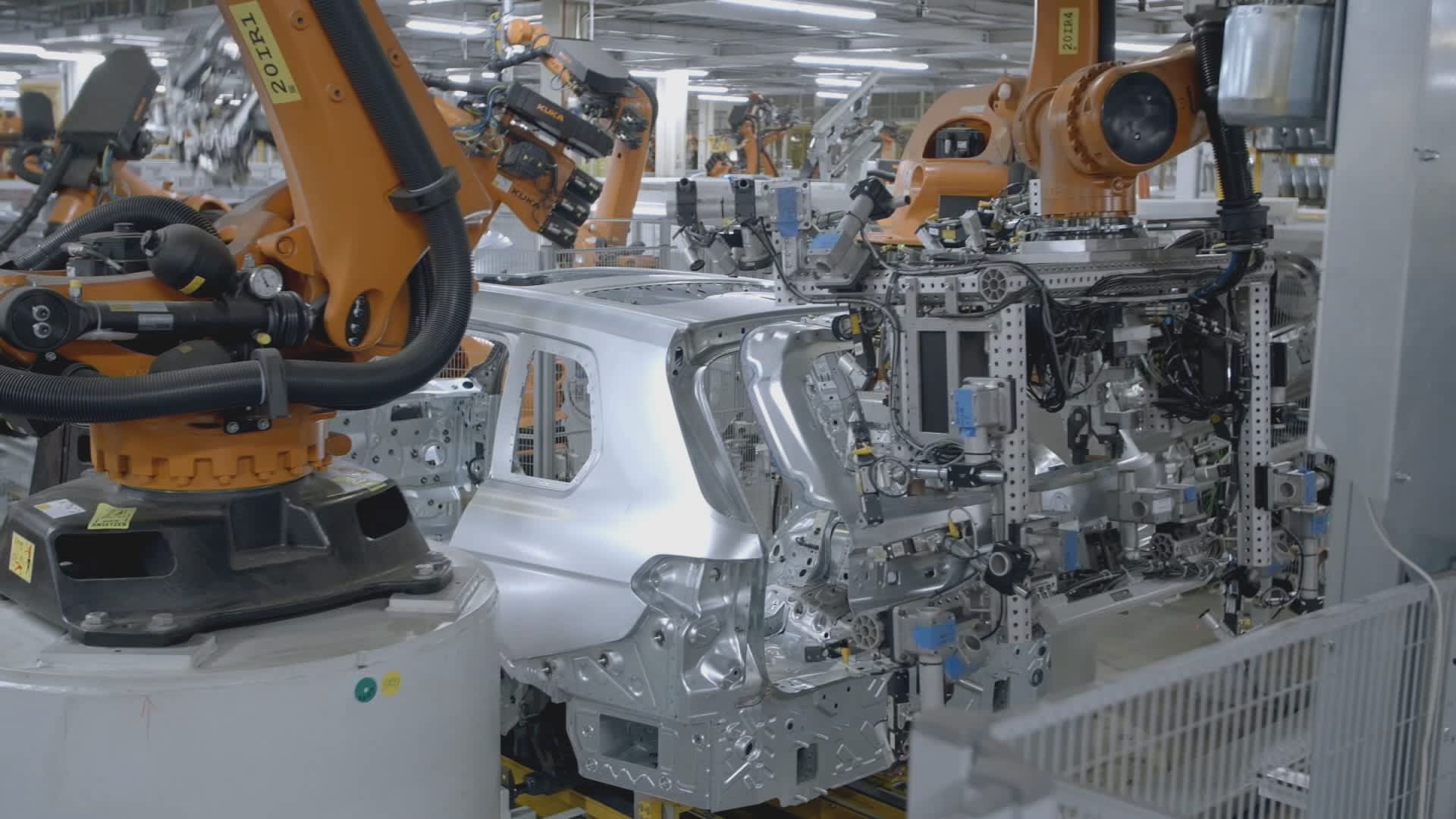

Within the physique store, robots weld between 300 and 400 metallic studs onto the body of each SUV. That is about half one million studs every day utilized by machines and now managed by AI.

Additional down the road, AI know-how checks to make sure each stud is exactly positioned, in keeping with BMW Group Supervisor Curtis Tingle. If a stud is misplaced, the system tells the robots to right it. No human intervention is required.

“It is a totally closed loop,” Tingle advised CNBC. “[AI] removes the human pondering, the human guide intervention, straight out of the equation.”

Tingle stated the brand new know-how has dramatically improved effectivity. “We’re reaching 5 occasions of what we thought was even potential earlier than, with what the AI is reaching now.”

In keeping with Tingle, the AI stud correction laser has already saved the corporate greater than $1 million a 12 months. The brand new tech, he stated, has allowed BMW to take away six employees from the road.

BMW advised CNBC the AI know-how is patent pending and was developed contained in the Spartanburg plant.

On the manufacturing facility flooring, BMW Group’s IT Challenge Lead Camille Roberts explains new AI software program helps velocity up the automaker’s present inspection course of.

As SUVs transfer down the road, 26 completely different cameras all through the ground snap images. That is when, in keeping with Roberts, “the AI kicks in, figuring out points and flagging them for a human to repair,” thus stopping an imperfect car from getting shipped out.

Roberts advised CNBC that earlier than the brand new AI improve, human employees could not verify each car to the extent they’ll now, including, “it is not likely humanly potential to examine each single automotive. … The manufacturing numbers simply would not meet the worldwide demand.”

Oliver Bilstein, BMW Group’s vp of logistics and manufacturing management, stated there’s nonetheless room to run for BMW’s AI know-how.

Staff on the plant put on what Bilstein calls manufacturing facility scanner gadgets that take measurements and high-resolution pictures of each centimeter of the manufacturing facility.

These pictures are used to construct a 3D “digital twin” of the plant, permitting BMW to immediately make changes and perceive the way it will have an effect on manufacturing earlier than it implements a change in the true world, Bilstein stated. BMW manufacturing facility planners around the globe can entry these detailed plans on-line.

With the assistance of recent AI software program, the scanning course of now takes days as an alternative of months, Bilstein stated.

Ultimately, such a AI know-how will be capable of be taught, by itself, the way to uncover and advocate new methods to make the BMW Group’s automated meeting line much more environment friendly, he stated.